Rigid box machines typically perform several basic operations in an automatic or semi-automatic manner. These operations include cutting, folding, gluing, and sometimes coating. The operation of the machines can vary depending on the material used and the type of box to be produced.

Cutting: Materials like cardboard or corrugated fiberboard are cut according to the dimensions of the box. This process is usually done with laser cutting technology, which requires high precision.

Folding: The cut materials are folded to form the shape of the box. This process ensures that the material is folded at the correct places and angles, making the box ready for assembly.

Gluing: The folded materials are glued together to maintain the shape of the box. This stage is crucial for the durability and aesthetic of the box.

Coating: In some cases, the outer surfaces of the boxes are coated to make them more visually appealing or to provide additional protection.

Types of Rigid Box Machines

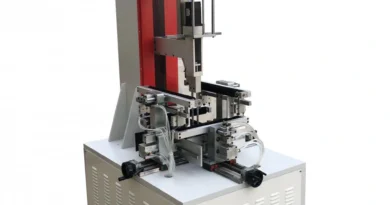

The variety of rigid box machines varies according to production needs and can be broadly categorized into two main types: automatic and semi-automatic machines.

Automatic Rigid Box Machines: These machines can perform all operations from cutting to gluing automatically. With high production speed and minimal human intervention required, they are ideal for large-scale productions.

Semi-Automatic Rigid Box Machines: Semi-automatic machines may require manual operations for some processes. For example, folding or gluing operations might be performed by an operator. They are suitable for small-scale productions or for products requiring custom designs.

Special Function Machines: Some rigid box machines are designed for specific designs or functions. For instance, there are special machines for making round boxes or for adding velvet lining to the interior part of the boxes.

Each of these machines optimizes the production process, providing efficiency in terms of both time and cost. Additionally, they are of great importance for the quality and consistency of rigid box production.