Revolutionizing Packaging: The Role of the Rigid Box Machine

Unleashing a Production Revolution with Rigid Box Machines

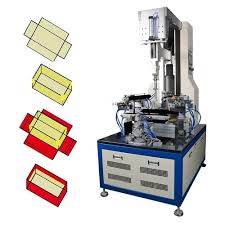

The packaging sector has undergone a significant transformation in recent years, thanks to the innovative features of the rigid box machine. Supplanting traditional packaging methods, the rigid box machine redefines industry standards with its high-speed and efficient production capabilities. These machines offer extraordinary precision and consistency in the manufacturing of rigid boxes, enhancing brand quality perception and reinforcing consumer loyalty.

The secret to a rigid box machine’s efficiency lies in its state-of-the-art technology. Equipped to perform cutting, folding, and gluing operations flawlessly within seconds, these machines leverage all the benefits of automation technology. This not only reduces labor costs but also perfects the timing in production processes, allowing for a swift response to market demands.

RİGİD BOX FORMİNG MACHİNERY

Pioneering Sustainable Packaging: Rigid Box Machines

The rigid box machine is not just a paragon of efficiency but also a leader in adopting sustainable packaging practices. Reducing waste and lowering energy consumption, these machines are the new face of eco-friendly production. Advanced rigid box machines are compatible with recyclable materials, thereby reducing the environmental impact of packaging waste without compromising the quality of the packaging.

Ideal for businesses that incorporate environmental sustainability into their brand mission, rigid box machines enable companies to create a positive environmental impact while also cultivating a greener brand image among consumers. Innovation and environmental responsibility will continue to shape the future of the packaging industry, driven by the capabilities of the rigid box machine.