Rigid Box Making Machines: Pioneering Excellence in Luxury Packaging

As the global market for luxury goods expands, the significance of premium packaging in brand strategy has escalated. A cornerstone in crafting such high-end packaging is the rigid box making machine—a sophisticated piece of equipment designed to produce sturdy, aesthetically pleasing boxes that resonate with luxury and quality. This article delves into the functionalities, benefits, and industry applications of rigid box making machines.

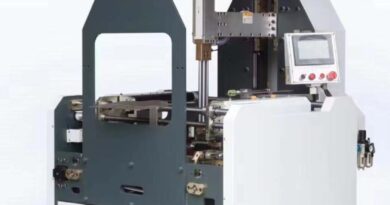

What is a Rigid Box Making Machine?

A rigid box making machine is an advanced automated system specifically engineered for creating rigid boxes, which are preferred for their durability and premium appearance. Unlike collapsible boxes, rigid boxes are made from dense paperboard that is cut, assembled, and often lined or covered with high-quality materials without the capability of being flattened.

How Does a Rigid Box Making Machine Operate?

The operation of a rigid box making machine involves several critical stages:

- Cutting: The machine precisely cuts the paperboard to specified dimensions, ensuring sharp, clean edges that are crucial for a premium finish.

- Assembling: Utilizing advanced gluing technologies, the cut pieces are assembled into a box shape. This stage may include the integration of reinforcements to ensure the box’s rigidity.

- Wrapping: This step involves wrapping the exterior of the box with various materials such as textured papers, fabrics, or leathers to enhance its tactile and visual appeal.

- Finishing: Additional decorative features such as embossing, foil stamping, or the addition of hardware like clasps and handles are applied to elevate the box’s luxury quotient.

Advantages of Rigid Box Making Machines

The deployment of rigid box making machines offers several distinct advantages:

- Precision and Consistency: Automated processes ensure each box is perfectly crafted to meet stringent quality standards.

- Efficiency: High automation levels significantly reduce production time and labor costs, facilitating large-scale production without sacrificing quality.

- Customization: Modern machines provide options for customization, allowing manufacturers to tailor boxes according to specific client demands or product dimensions.

- Sustainability: Many rigid box making machines are designed to minimize waste and maximize the use of recyclable materials, aligning with the increasing demand for sustainable production practices.

Applications in the Luxury Market

Rigid boxes are synonymous with high-end products due to their robustness and elegant presentation. They are widely used in several luxury sectors, including:

- Jewelry and Watches: Offering superior protection and a display worthy of high-value items.

- Cosmetics and Fragrances: Enhancing brand image and consumer experience through exquisite packaging.

- Gourmet Foods and Confectionery: Preserving the quality and extending the shelf life of premium edibles.

- Consumer Electronics: Providing durable and attractive packaging for gadgets, often seen in the unboxing experiences shared on social media.

Conclusion

Rigid box making machines play a pivotal role in the packaging industry, especially in sectors where the unboxing experience is integral to the consumer’s perception of value. As brands continue to seek innovative ways to engage and impress consumers, the importance of advanced packaging solutions like those provided by rigid box making machines will only grow. These machines not only cater to the aesthetic and functional requirements of luxury packaging but also enhance operational efficiencies, making them an indispensable asset in the realm of high-end retail.