التقدم في آلات صنع الصناديق الصلبة: الابتكارات التي تشكل صناعة التعبئة والتغليف

In the packaging world, the demand for sturdy and aesthetically appealing packaging has led to significant technological advancements in rigid box making machinery. These machines are crucial for producing high-quality, durable boxes used for luxury goods, electronics, and high-end cosmetics.

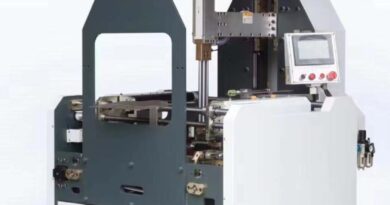

Modern rigid box making machines incorporate cutting-edge technologies such as PLC (Programmable Logic Controller) systems, which enable precise control over the production process, enhancing both efficiency and product quality. Automation is a key feature, with many machines now capable of handling various production stages—from paper feeding and gluing to assembling and finishing—without significant human intervention.

Additionally, digital integration allows operators to quickly adjust machine settings for different box sizes and styles, significantly reducing setup time and material waste. Vision inspection systems have also been integrated into these machines, ensuring that each box meets strict quality standards by detecting and rejecting defects in real-time.

The use of eco-friendly materials is another significant trend in the rigid box manufacturing industry. Advanced machinery now supports the use of recycled and sustainable materials, aligning with global sustainability efforts and consumer preferences for environmentally responsible products.

These technological enhancements not only improve the efficiency and flexibility of box production but also allow manufacturers to respond swiftly to evolving market trends and consumer demands. As a result, rigid box making machinery continues to play a pivotal role in the packaging industry, driving innovation and supporting the delivery of superior product packaging solutions.