إحداث ثورة في التعبئة والتغليف باستخدام آلات صنع الصناديق الصلبة المتقدمة

مقدمة: In the competitive world of product packaging, the quality and durability of packaging not only protect the product but also significantly enhance its market appeal. Rigid box making machines are at the forefront of this sector, automating the production of high-quality, durable boxes favored by luxury brands and high-end electronics manufacturers. This article explores the functionalities, benefits, and industry applications of rigid box making machines.

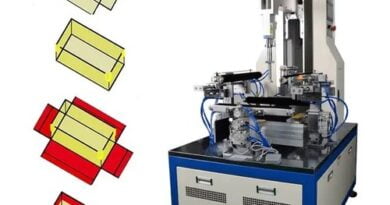

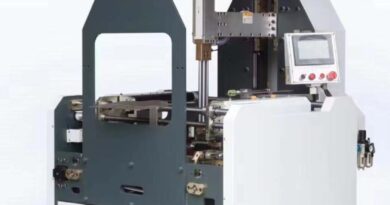

ما هي آلة صنع الصناديق الصلبة؟ A rigid box making machine is an industrial device designed to automate the creation of rigid boxes, which are sturdy, non-collapsible containers made from heavy paperboard. Unlike folding cartons, rigid boxes are typically constructed with a separate wrapped and glued paper over a heavy chipboard frame, providing a premium feel. These machines streamline complex processes such as die-cutting, wrapping, and assembling, significantly improving production efficiency and consistency.

الميزات الرئيسية لآلات صنع الصناديق الصلبة:

- High Precision and Control: These machines offer precise control over every aspect of the box making process, from cutting and fitting to gluing and finishing, ensuring that each box is perfectly crafted.

- Customization Options: They allow for extensive customization in terms of size, shape, and materials used, enabling the production of bespoke packaging solutions tailored to specific client needs.

- Efficiency in Production: With capabilities for high-speed assembly, these machines can produce large volumes of boxes quickly, meeting the demands of high-paced production schedules.

- أتمتة: Advanced automation reduces the need for manual labor, lowering production costs and minimizing the potential for human error.

فوائد آلات صنع الصناديق الصلبة:

- تعزيز الإنتاجية: Automated processes speed up production, allowing manufacturers to fulfill large orders more efficiently.

- Superior Quality: The precision engineering of these machines ensures that each box meets high-quality standards with consistent construction and appearance.

- Cost-Effectiveness: By automating the production process, these machines help reduce labor costs and increase throughput, making high-end packaging more economically viable.

- الاستدامة: Modern rigid box making machines are designed to optimize material use and reduce waste, supporting more sustainable production practices.

Applications Across Various Industries:

- تغليف السلع الفاخرة: Essential for the production of high-end packaging for luxury items such as perfumes, watches, and designer accessories.

- Gourmet Food Products: Used for crafting attractive and durable boxes for premium food items, enhancing the unboxing experience.

- Consumer Electronics: Ideal for manufacturing protective yet stylish packaging for electronics that require a high level of protection against damage.

- Corporate Gifts: Provides exquisite packaging solutions for corporate gifts and promotional items, adding to the perceived value of the contents.

خاتمة: Rigid box making machines are transforming the landscape of product packaging, providing companies with the tools to create high-quality, durable, and attractive packaging that stands out in the marketplace. By integrating these advanced machines into their production lines, manufacturers can not only meet the growing demand for premium packaging but also enhance their operational efficiency and sustainability. As consumer expectations continue to evolve towards more luxurious and eco-friendly packaging, the role of rigid box making machines will become increasingly crucial in the industry, driving innovation and excellence in packaging design and production.