Comprehensive Overview of Rigid Box Making Machinery: Functions, Types, and Industry Applications

Purpose and Function

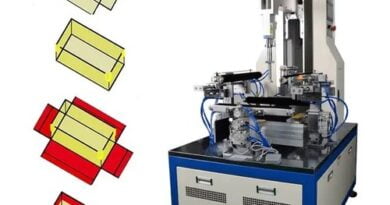

Rigid box making machinery is designed to automate the production of high-quality boxes used in luxury packaging for products such as electronics, cosmetics, and fine foods.

These machines handle various tasks including cutting, assembling, and finishing boxes with precision and speed.

Types of Machinery

There are several types of machines involved in the production process, including die cutters, gluing machines, and wrapping machines.

Each type plays a specific role, such as die cutters shaping the cardboard and gluing machines applying adhesives to secure box parts.

Advantages of Automation

Automation in box making increases production speed and consistency while reducing labor costs and human error.

It allows for the mass production of uniform boxes that meet strict quality standards.

Materials Processed

These machines typically work with a range of materials including various grades of paperboard, cardboard, and sometimes even plastics or fabrics for luxury finishes.

Material choice impacts the final appearance and durability of the box.

Customization Capabilities

Modern rigid box making machines offer customization options, allowing manufacturers to produce boxes of various sizes, shapes, and designs to meet specific customer requirements.

They can also incorporate features like embossing, debossing, and window patching.

Maintenance and Upkeep

Regular maintenance is crucial for ensuring the longevity and efficient operation of box making machinery.

This typically includes routine checks, lubrication of moving parts, and replacement of worn-out components.

Environmental Considerations

Manufacturers are increasingly opting for machines that are energy-efficient and capable of processing recyclable or biodegradable materials, in response to growing environmental concerns.

This shift is part of a broader trend towards more sustainable manufacturing practices in the packaging industry.

Market Trends

The demand for rigid box making machinery is influenced by trends in consumer electronics, luxury goods, and environmental regulations.

Technological advancements are continually shaping this market, with newer models featuring enhanced automation and energy efficiency.

Challenges and Solutions

Common challenges include the high initial cost of machinery and the need for skilled operators.

Solutions often involve training programs for operators and financing options to help businesses manage the investment in advanced machinery.