Innovations in Packaging: The Impact and Mechanism of Rigid Box Making Machines

The packaging industry continually seeks innovative solutions to enhance product presentation and durability. One such innovation is the rigid box making machine, which is crucial for crafting premium, non-collapsible packaging used primarily in luxury markets. This article delves into the mechanisms, uses, and advantages of rigid box making machines, highlighting their pivotal role in modern packaging technologies.

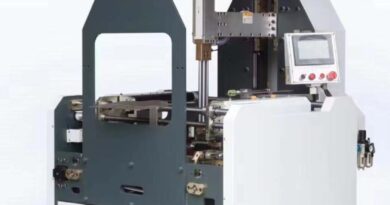

What is a Rigid Box Making Machine?

A rigid box making machine is a specialized device designed to manufacture high-quality, sturdy boxes, known as rigid boxes. Unlike typical folding cartons, these boxes are constructed from heavier, more durable materials such as thick cardboard or chipboard. The boxes produced are notable for their structural rigidity and are not meant to be flattened or collapsed.

Key Components and Functions

The functionality of a rigid box making machine encompasses several stages of production:

- Cutting: The machine starts with precision cutting of the board material into required shapes and sizes.

- Gluing: Adhesive is applied to the cut pieces to facilitate assembly.

- Wrapping: The external surfaces are often wrapped with various materials, including paper, fabric, or leather, adding to the aesthetic and tactile quality of the box.

- Assembling: The machine assembles the pieces into a finished rigid box, ensuring accurate alignment and secure attachment.

These components work in concert to automate the box-making process, significantly improving the efficiency and consistency of production.

Advantages of Using Rigid Box Making Machines

The introduction of rigid box making machines into the packaging process offers multiple advantages:

- Efficiency: These machines streamline the production process, allowing for rapid creation of large quantities of boxes with minimal human intervention.

- Precision and Quality: Automated manufacturing ensures that each box is crafted with uniform quality and precise dimensions, essential for premium packaging needs.

- Customization: With advanced technology, these machines can quickly adjust to produce boxes of various sizes and designs, accommodating diverse product specifications and branding requirements.

- Cost-effectiveness: Despite the high initial investment, the long-term benefits include reduced labor costs and decreased material wastage, leading to improved overall profitability.

Applications in the Industry

Rigid boxes are favored for packaging products where protection and presentation are paramount. Typical applications include:

- Luxury goods such as jewelry and designer wear

- High-end electronics and accessories

- Cosmetics and fragrances

- Specialty gourmet items and confections

Conclusion

Rigid box making machines are essential tools in the packaging industry, enabling brands to enhance their product presentation while ensuring robust protection. As the market for luxury and premium goods continues to grow, the importance of such innovative technologies becomes increasingly significant. These machines not only support high standards in packaging but also contribute to the operational efficiency and economic viability of packaging businesses worldwide.