Potenziare il packaging di lusso: il ruolo delle macchine per la produzione di scatole rigide

Nel regno dei beni di lusso, l'imballaggio non serve solo come copertura protettiva, ma anche come dichiarazione di qualità e prestigio del marchio. Le macchine per la fabbricazione di scatole rigide sono in prima linea nella creazione di soluzioni di imballaggio di fascia alta, fornendo gli strumenti necessari per produrre scatole robuste e visivamente accattivanti. Queste macchine sono fondamentali per i marchi che mirano a consegnare i loro prodotti con stile, garantendo al contempo durata e qualità. Questo articolo approfondisce la tecnologia alla base delle macchine per la fabbricazione di scatole rigide, evidenziandone l'importanza nel settore degli imballaggi di lusso.

Cos'è una macchina per la produzione di scatole rigide?

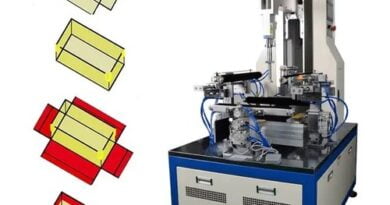

Una macchina per la fabbricazione di scatole rigide è un dispositivo industriale progettato per produrre scatole robuste e non pieghevoli, utilizzate principalmente per beni di lusso. Queste scatole sono solitamente realizzate con materiali più densi e di qualità superiore, come cartone spesso o truciolato, che non sono progettati per essere piegati in piano. La macchina automatizza il processo di taglio, assemblaggio e finitura di queste scatole, che sono rinomate per la loro integrità strutturale e il loro fascino estetico.

Principi di funzionamento delle macchine per la fabbricazione di scatole rigide

La creazione di una scatola rigida è un processo in più fasi facilitato dalla macchina per la fabbricazione di scatole rigide:

- Preparazione del materiale:Il processo inizia con la preparazione e il taglio del cartone secondo specifiche precise, assicurando che tutti i pezzi si adattino perfettamente tra loro.

- Incollaggio e assemblaggio: I componenti della scatola vengono poi incollati insieme. Macchine avanzate assicurano che l'adesivo venga applicato in modo preciso ed efficiente, formando un legame forte che mantiene la forma e la rigidità della scatola.

- Avvolgimento: Lo strato esterno della scatola è spesso carta di alta qualità, tessuto o altro materiale che ne esalta l'aspetto visivo. La macchina avvolge questi materiali attorno alla scatola in modo uniforme, creando una finitura pulita e attraente.

- Finitura: In questa fase finale è possibile integrare ulteriori abbellimenti, come la goffratura, la stampa a caldo o l'aggiunta di chiusure come magneti o nastri, aggiungendo un tocco di lusso e migliorando l'esperienza di unboxing.

Vantaggi delle macchine per la produzione di scatole rigide

- Precisione e Qualità:I processi automatizzati garantiscono che ogni scatola venga realizzata con la massima precisione, mantenendo una qualità costante in tutti i lotti.

- Efficienza:Queste macchine velocizzano notevolmente la produzione rispetto all'assemblaggio manuale, consentendo ai produttori di soddisfare grandi ordini con tempi di evasione più rapidi.

- Personalizzazione: Le macchine per la produzione di scatole rigide possono essere regolate per produrre diverse dimensioni e design, consentendo la personalizzazione in base alle dimensioni specifiche del prodotto o alle preferenze estetiche.

- Sostenibilità: Ottimizzando l'uso dei materiali e riducendo gli sprechi, queste macchine supportano anche pratiche di produzione più sostenibili.

Applicazioni nel mercato del lusso

Le scatole rigide sono preferite in diversi settori di fascia alta, tra cui:

- Gioielli e Orologi: Fornire imballaggi eleganti e sicuri che esaltino il valore di pezzi finemente lavorati.

- Cosmetici e Profumi:Utilizzando scatole personalizzate che riflettono la qualità e l'essenza dei prodotti di bellezza di alta qualità.

- Tecnologia ed elettronica: Racchiudere i gadget in scatole rigide che trasmettono raffinatezza e design all'avanguardia.

- Cibi e dolci gourmet: Garantire che i prodotti commestibili di alta qualità siano presentati e conservati in confezioni che ne esaltino l'esclusività e il gusto.

Conclusione

Le macchine per la produzione di scatole rigide sono indispensabili nel settore degli imballaggi di lusso, dove lo standard dell'imballaggio deve corrispondere alla qualità premium dei prodotti che contiene. Grazie ai progressi tecnologici, queste macchine sono diventate fondamentali per garantire che gli articoli di lusso non siano solo ben protetti, ma anche presentati in modo accattivante, migliorando il valore del marchio e la soddisfazione del cliente. Man mano che le aspettative dei consumatori continuano a crescere, l'importanza di queste macchine nella fornitura di soluzioni di imballaggio di alto livello non potrà che crescere, rafforzando il loro ruolo di spina dorsale del settore degli imballaggi di lusso.