Skip to content

Rigid boxes, preferred for their durability and premium presentation, are crucial in the packaging industry, especially for luxury goods and electronics. This paper explores the technological enhancements in the machinery used to produce these boxes, including the challenges and opportunities these advancements present.

- Technological Enhancements:

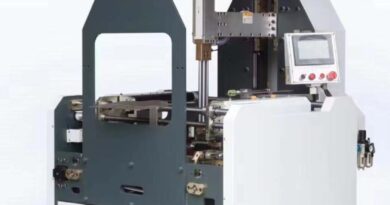

- Automation and Control Systems: The use of sophisticated automation technologies in rigid box making machines has significantly reduced manual labor, minimized errors, and increased production speeds. Advanced sensors and control systems ensure precision in box dimensions and quality, facilitating consistent output across large volumes.

- Material Handling Innovations: Modern machines now feature improved material handling mechanisms that accommodate a broader range of materials and thicknesses, enhancing flexibility in box design and production. These innovations also reduce material wastage, contributing to cost efficiency and environmental sustainability.

- Digital Integration and IoT: Integration of digital technologies and the Internet of Things (IoT) in rigid box machinery allows for real-time monitoring and analytics. This connectivity enables predictive maintenance, efficient resource management, and timely adjustments to production processes, further optimizing operations.

- Environmental Impact: Innovations in rigid box manufacturing also focus on reducing the environmental footprint of production processes. Energy-efficient motors, better waste management systems, and the use of recycled materials are prominent features of new models. These steps help manufacturers meet stricter environmental regulations and consumer expectations for sustainable practices.

- Case Studies: Several industry leaders have adopted these new technologies, resulting in remarkable gains. For example, a major packaging company implemented a fully automated rigid box production line, achieving a 40% increase in production efficiency and a significant reduction in operational costs.

- Challenges and Future Directions: While technological advancements bring numerous benefits, they also pose challenges such as high capital investment, the need for skilled technicians, and integration issues with existing systems. Future developments are expected to focus on further automation, artificial intelligence, and environmentally friendly technologies.

- Conclusion: The evolution of rigid box making machinery is poised to transform the packaging industry. As manufacturers increasingly adopt these advanced technologies, they not only enhance their operational efficiency but also contribute to a more sustainable production model.