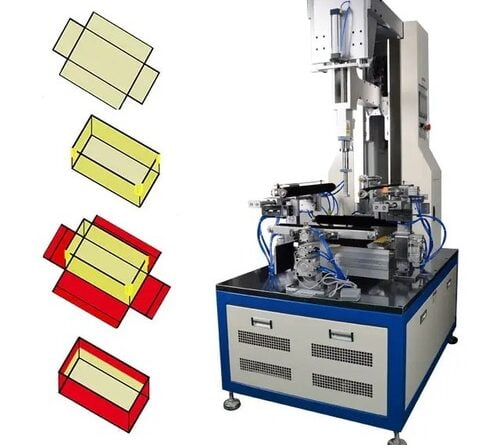

Rigid box forming machine

1. The Evolution of Rigid Box Forming Machines

Rigid box forming machines have revolutionized the packaging industry, offering unprecedented efficiency and quality in box production. Initially, rigid boxes were crafted manually, involving labor-intensive processes that limited production speed and consistency. With technological advancements, modern machines now feature automated systems for precise cutting, gluing, and assembling, ensuring uniformity and high-quality finishes. These machines accommodate a range of materials and designs, from simple shapes to complex structures, catering to the luxury goods market where packaging is as important as the product itself. The evolution from manual craftsmanship to automated precision underscores the industry’s shift towards innovation and efficiency, highlighting the critical role of these machines in meeting the growing demand for high-end packaging solutions.

2. How Rigid Box Forming Machines Work

Rigid box forming machines are at the heart of the packaging industry, designed to automate the creation of high-quality boxes. These machines typically integrate several modules to perform various tasks such as die-cutting, wrapping, gluing, and assembling. Advanced models are equipped with programmable logic controllers (PLCs) and servo motors, enabling precise control over production processes. A key feature is their ability to use camera-based systems for accurate alignment of materials, ensuring each box is perfectly formed. The process starts with feeding the board and cover material into the machine, followed by precise cutting and gluing. The machine then wraps the cover material around the board, forming the rigid box with exact dimensions and a flawless finish. This automation streamlines production, enhances quality, and allows for customization, meeting diverse market needs.

3. The Importance of Rigid Box Forming Machines in the Luxury Market

Rigid box forming machines have become indispensable in the luxury market, where packaging plays a crucial role in branding and customer experience. These machines enable producers to create premium boxes that not only protect valuable products but also enhance brand perception through exquisite design and quality. The ability to produce boxes with a variety of textures, finishes, and intricate designs allows brands to stand out in a competitive market. Moreover, the efficiency and precision of these machines reduce production costs and waste, making high-quality packaging more accessible. As consumers continue to value packaging aesthetics and sustainability, the importance of rigid box forming machines in producing eco-friendly and visually appealing packaging solutions grows, reinforcing brand values and appealing to environmentally conscious buyers.

4. Challenges and Solutions in Rigid Box Forming Machine Operations

Operating rigid box forming machines involves several challenges, including material handling, machine setup, and maintenance. One common issue is the precise alignment of materials to avoid waste and ensure product quality. Manufacturers address this challenge by integrating advanced sensors and camera systems for real-time adjustments. Another concern is the machine’s flexibility to accommodate various box sizes and styles, which is crucial for meeting custom orders. Solutions include modular designs and programmable settings, allowing for quick changes and versatile production capabilities. Additionally, regular maintenance and upgrades are vital to keep the machines running efficiently and to extend their lifespan. Manufacturers and operators often invest in training programs to equip their staff with the necessary skills to tackle these challenges, ensuring continuous improvement in production processes.

5. Future Trends in Rigid Box Forming Machine Technology

The future of rigid box forming machine technology is geared towards increased automation, sustainability, and customization. Innovations such as AI and IoT integration are set to further optimize production processes, enabling predictive maintenance, real-time monitoring, and automated quality control. These advancements will not only improve efficiency but also reduce downtime and operational costs. Sustainability is another key trend, with machines increasingly designed to work with eco-friendly materials and minimize waste. Customization capabilities are also expanding, with more sophisticated software allowing for greater design flexibility and faster setup times for small, custom orders. As the packaging industry continues to evolve, these technological advancements will drive the development of rigid box forming machines, meeting the changing needs of manufacturers and consumers alike.

These articles provide a comprehensive overview of the current state and future direction of rigid box forming machine technology and its impact on the packaging industry.