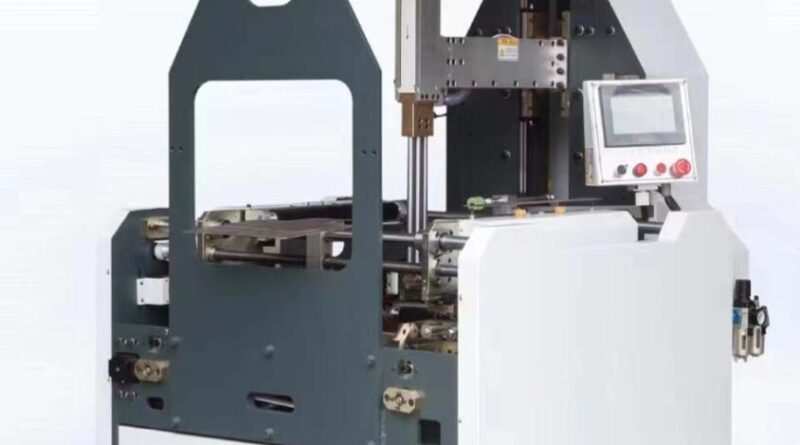

Rigid box forming machine

Rigid box forming machines play a pivotal role in the production of high-quality, durable boxes used predominantly for packaging luxury goods, electronics, cosmetics, and other premium products. These machines significantly automate the production process, enhancing both efficiency and product quality in comparison to manual assembly methods.

Typically utilizing materials such as cardboard or hardboard, these machines begin their process by feeding pre-cut material into the system. Pre-forming operations such as cutting, creasing, and scoring are conducted to prepare the material for assembly. Following these preparatory steps, adhesive is applied to designated areas, and the material is folded and shaped into a box. The precision in adhesive application and placement ensures that the boxes are constructed with strong, clean bonds, contributing to the overall quality and durability of the final product.

The benefits of using rigid box forming machines include increased production speed, consistency in the size and shape of each box, superior quality, and cost-effectiveness. These machines are capable of producing large quantities of boxes in a relatively short time frame, far surpassing manual assembly speeds. Automated forming guarantees uniformity across products, a crucial factor for brands where packaging reflects on product quality.

Rigid box forming machines find applications across various sectors, including luxury items, electronics, cosmetics and perfumes, as well as gourmet foods and confections. The rigid boxes produced for these sectors not only convey a sense of quality and luxury but also provide protection and enhance presentation.

Despite the high initial investment, rigid box forming machines offer significant savings over time by increasing production efficiency and reducing labor costs. Their use underscores a brand’s commitment to quality and luxury, directly impacting consumer satisfaction. In conclusion, rigid box forming machines are indispensable in the packaging industry, offering efficient, consistent, and high-quality solutions for premium packaging needs.