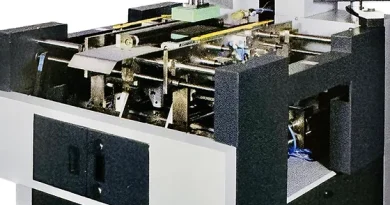

The Advantages of Rigid Box Machines

Rigid box machines offer a wide array of benefits to manufacturers, enhancing efficiency, quality, and productivity in the packaging sector. These machines, designed for the production of high-quality, durable boxes, play a crucial role in meeting the packaging needs of various industries, including luxury goods, electronics, cosmetics, and more. Below are some key advantages of using rigid box machines:

Increased Production Efficiency

One of the primary benefits of rigid box machines is their ability to significantly increase production efficiency. These machines automate the processes of cutting, folding, gluing, and coating, which reduces the time required to produce each box. Automation allows for consistent production speeds and can help manufacturers meet high demand without sacrificing quality.

Enhanced Product Quality

Rigid box machines are known for their precision and consistency, which contribute to superior product quality. The accuracy of cutting and folding operations ensures that each box is perfectly shaped and sized, enhancing the overall appearance and functionality of the packaging. This precision is particularly important for luxury packaging, where the aesthetic appeal and perfection of the box are paramount.

Cost Savings

By automating the production process, rigid box machines reduce the need for manual labor, which can lead to significant cost savings. Although the initial investment in machinery might be high, the reduction in labor costs and the increase in production speed mean that the return on investment can be rapid. Additionally, the efficiency of these machines can reduce waste materials, further lowering production costs.

Versatility

Modern rigid box machines offer versatility in terms of the types of boxes they can produce. From simple square or rectangular shapes to more complex designs with unique folds and closures, these machines can handle a variety of specifications. This versatility allows manufacturers to cater to a wide range of packaging needs and to offer custom packaging solutions to their clients.

Improved Worker Safety

Automating the box production process reduces the risk of injuries that can occur with manual operations, such as cutting and folding. This makes the manufacturing environment safer for workers, which is not only a moral and legal responsibility but can also contribute to higher worker satisfaction and productivity.

Sustainability

With an increasing focus on sustainability, rigid box machines offer the benefit of more efficient use of materials, reducing waste. Many machines are designed to minimize excess material during the cutting and folding processes, and the ability to recycle offcuts and use eco-friendly materials further enhances the sustainability of the packaging production process.

Competitive Edge

Utilizing rigid box machines can give manufacturers a competitive edge in the marketplace. The ability to produce high-quality, aesthetically pleasing, and durable packaging can make a significant difference in consumer product choices, particularly in sectors where packaging plays a crucial role in product differentiation.

In conclusion, the advantages of rigid box machines are multifaceted, offering not just tangible benefits in terms of production efficiency and cost savings, but also enhancing the quality and sustainability of packaging. As the demand for premium packaging continues to grow, the role of these machines in meeting such demands efficiently and effectively will undoubtedly increase.