“包装革命:探索硬盒制造机械的最新技术进步和未来趋势”

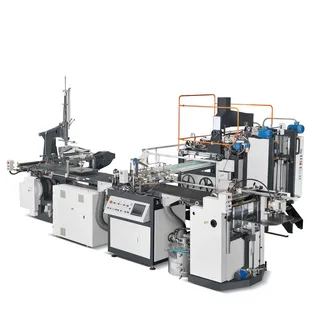

In the competitive landscape of packaging production, rigid box making machinery stands out for its critical role in manufacturing high-quality, durable packaging solutions. As demands for aesthetically pleasing and sturdy packaging soar, the technology behind rigid box making machinery continues to evolve. This article delves into the latest technological advancements and their implications for the packaging industry.

Technological Advancements in Rigid Box Making

- Automation and Robotics: Recent innovations in rigid box making machinery focus heavily on automation to reduce human error and increase production speed. Robotics has been integrated to handle tasks such as precise cutting, folding, and assembly, which are crucial for maintaining consistency in quality.

- Computerized Control Systems: Advanced computerized control systems are now commonplace in modern rigid box making machines. These systems provide operators with precise control over every aspect of the box making process, from material handling to glue application, ensuring that each box meets exact specifications.

- 3D Visualization Tools: Some of the latest rigid box making machines are equipped with 3D visualization software, allowing designers to create and simulate the final product before the manufacturing process begins. This tool helps in minimizing waste by ensuring that the design is free of flaws before production.

- Eco-friendly Technologies: In response to increasing environmental concerns, manufacturers have developed more sustainable technologies within rigid box making. These include the use of eco-friendly adhesives and recyclable materials, as well as machines designed to minimize energy consumption.

对包装行业的影响

The integration of these advanced technologies in rigid box making machinery has multiple impacts on the packaging industry:

- Increased Efficiency: Automation and enhanced control systems significantly increase the speed of production while reducing labor costs.

- Improved Quality Control: High precision tools and technologies ensure that each box is produced with consistent quality, reducing the rate of defects and returns.

- 可持续发展: By adopting eco-friendly materials and processes, manufacturers are not only reducing their environmental impact but are also appealing to the eco-conscious consumer.

未来的趋势

Looking ahead, the rigid box making machinery sector is likely to embrace more AI-driven solutions to further optimize production processes. Predictive maintenance, powered by AI, could become a norm, reducing downtime and operational costs. Additionally, the rise of customization and personalization in packaging will drive demand for more flexible and adaptable machinery.

结论

As the rigid box making machinery continues to incorporate cutting-edge technologies, its influence on the packaging industry grows more significant. Through automation, advanced computing, and sustainable practices, these machines are setting new standards in packaging production, promising a future where efficiency and quality go hand in hand.