Avances en automatización e ingeniería de precisión

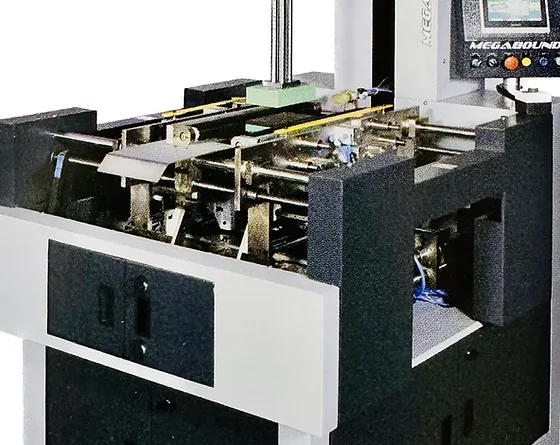

One of the most significant shifts has been the increased reliance on automation and precision engineering in rigid box manufacturing. Modern machinery now incorporates advanced sensors and control systems that ensure boxes are crafted with utmost precision, resulting in a superior fit and finish. This automation extends to the entire production line, from material handling to assembly and inspection, reducing labor costs and human error while increasing production speed.

Integration of Sustainable Manufacturing Practices

Sustainability has become a cornerstone of manufacturing practices, and rigid box making machinery has adapted to support eco-friendly production methods. New machines are designed to be more energy-efficient and to work seamlessly with recycled and biodegradable materials. This shift not only reduces the environmental impact of packaging production but also caters to the growing consumer demand for sustainable products.

Customization Through Digital Technologies

Digital technologies have revolutionized the way rigid boxes are designed and produced. Cutting-edge software enables manufacturers to easily customize box sizes, shapes, and designs, meeting the bespoke needs of clients without the necessity for extensive retooling. Digital printing technology further enhances customization, allowing for high-resolution, multi-color designs to be printed directly onto the boxes, making the packaging itself a key part of the product branding.

The Role of Artificial Intelligence and Machine Learning

Artificial Intelligence (AI) and Machine Learning (ML) are being integrated into rigid box making machinery to optimize production processes. AI algorithms can predict maintenance needs, reducing downtime, and ML can analyze production data to identify efficiency improvements. These technologies also support quality control, with systems capable of detecting and correcting errors in real-time, ensuring consistent quality across production batches.

Connectivity and Smart Factories

The concept of smart factories has permeated the packaging industry, with rigid box making machinery becoming increasingly connected. This connectivity allows for real-time monitoring and control of production processes, facilitating remote troubleshooting and maintenance. It also enables manufacturers to better track and manage inventory, leading to more efficient operations and reduced waste.