Rigid Box Making Machinery: Transforming Packaging with Advanced Automation

In the highly competitive world of packaging, the quality of a product’s packaging can significantly enhance its market appeal. Rigid box making machinery is crucial for businesses looking to produce high-quality, durable packaging solutions that stand out. This article explores what rigid box making machinery is, its key benefits, and how it revolutionizes the packaging industry.

What is Rigid Box Making Machinery?

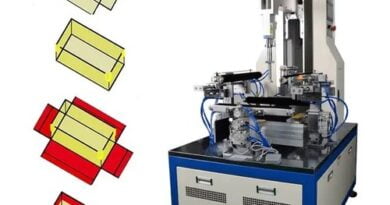

Rigid box making machinery is specialized equipment used to manufacture sturdy, high-end packaging typically used for luxury goods, electronics, and premium consumer products. Unlike standard flexible packaging, rigid boxes are made from substantially stiffer paperboard permanently glued into the desired shape. This machinery automates various processes such as die-cutting, creasing, assembling, and gluing, enabling the production of boxes that are not only visually appealing but also protective and durable.

Key Benefits of Rigid Box Making Machinery

- Enhanced Durability and Protection: Rigid boxes are known for their strength and durability. The machinery ensures that each box is precisely crafted to provide optimal protection for its contents, making them ideal for fragile or high-value items.

- Superior Aesthetic Appeal: This equipment allows for the integration of various design elements, such as embossing, debossing, and intricate closures, which enhance the tactile and visual appeal of the packaging. Such features are crucial for brands that want to make a strong impression on consumers.

- Increased Production Efficiency: Rigid box making machinery automates critical steps in the box making process, significantly speeding up production while maintaining high standards of quality. This efficiency is vital for meeting market demand, especially during peak seasons.

- Cost-Effectiveness: While the initial investment in rigid box making machinery may be significant, the long-term savings in labor costs, reduced waste, and improved production speed offer substantial cost benefits to manufacturers.

- Sustainability: Modern rigid box making machines are designed to operate with minimal waste, optimizing material usage and often accommodating recycled materials. This contributes to more sustainable production practices, which is increasingly important to consumers and businesses alike.

Industries That Benefit from Rigid Box Making Machinery

- Luxury Goods: High-end products such as jewelry, designer apparel, and luxury cosmetics often require packaging that matches the quality of the contents. Rigid boxes provide the necessary elegance and protection.

- Electronics: Due to their robust construction, rigid boxes are ideal for packaging electronics that need extra protection from mechanical and environmental stresses.

- Gifting and Retail: Rigid boxes enhance the unboxing experience, making them perfect for gift packaging and premium retail products where first impressions count.

Conclusion

Rigid box making machinery is a game-changer in the packaging industry, providing businesses with the tools to create high-quality, durable, and attractive packaging solutions. Investing in this machinery not only elevates the standard of packaging but also streamlines production processes, enhances brand reputation, and can lead to increased customer satisfaction. As the demand for premium packaging continues to grow, rigid box making machinery stands out as a vital asset for manufacturers looking to capitalize on this trend.