The Evolution and Impact of Rigid Box Making Machinery in the Packaging Industry

In the rapidly evolving packaging industry, the advent of rigid box making machinery has marked a revolutionary shift. This sophisticated equipment has not only streamlined the manufacturing process but also significantly enhanced the quality and durability of packaging solutions. As businesses continually seek innovative ways to package their products, the role of rigid box making machinery has become increasingly pivotal.

The Backbone of Modern Packaging Solutions

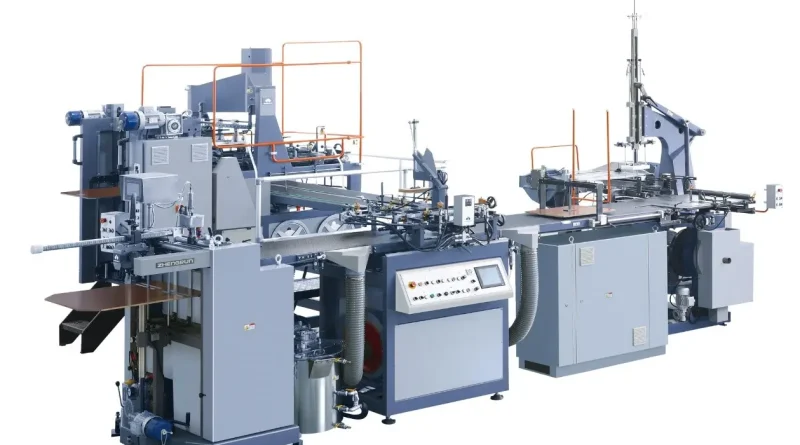

Rigid boxes, known for their sturdiness and premium appearance, are a preferred choice for luxury goods, electronics, and high-end retail products. The transition from manual assembly to the use of automated rigid box making machinery has allowed manufacturers to achieve precision, efficiency, and scalability. These machines employ advanced technology to cut, fold, and glue cardboard in a manner that ensures uniformity and quality across large volumes of production.

Technological Advancements in Machinery

The latest models of rigid box making machinery come equipped with cutting-edge features such as computerized control systems, high-speed automation, and customizable modules. These advancements enable manufacturers to produce boxes of various sizes, shapes, and designs, catering to the diverse needs of different industries. Furthermore, the integration of digital printing technology has opened up new possibilities for custom branding and decoration, allowing businesses to enhance their packaging aesthetics directly during the manufacturing process.

Sustainability and Eco-Friendliness

With a growing emphasis on sustainability, manufacturers are increasingly adopting rigid box making machinery that supports the use of eco-friendly materials. Modern machines are designed to minimize waste and energy consumption, contributing to more sustainable production practices. The ability to use recycled cardboard and biodegradable adhesives further aligns with global efforts to reduce the environmental impact of packaging waste.

Economic Implications

The efficiency and speed of rigid box making machinery translate into significant cost savings for manufacturers. By reducing labor costs and minimizing material wastage, businesses can achieve a better return on investment. Additionally, the enhanced durability and aesthetic appeal of rigid boxes can increase product value, allowing brands to position themselves more favorably in competitive markets.

The Future Outlook

As consumer preferences continue to evolve towards personalized and sustainable packaging options, the demand for advanced rigid box making machinery is expected to grow. Innovations in machine design and functionality, along with the integration of artificial intelligence and robotic automation, are likely to shape the future of this industry.

In conclusion, rigid box making machinery has become an indispensable tool in the packaging industry, driving innovation, sustainability, and economic efficiency. As technology continues to advance, the potential of these machines to transform packaging standards and practices is boundless, promising a future where packaging is not just functional but also a statement of brand identity and environmental responsibility.