硬盒制造机械是生产高质量包装解决方案必不可少的,近年来,硬盒制造机械经历了重大的技术进步。这些创新不仅提高了效率和生产力,还确保了可持续性和定制化,满足了电子、化妆品和奢侈品等各个行业不断变化的需求。

1. Integration of Artificial Intelligence (AI) and Machine Learning (ML)

The integration of AI and ML into rigid box making machinery represents a groundbreaking development. These technologies enable machines to learn from past production runs, optimizing settings and operations for improved speed, precision, and material usage. For instance, AI algorithms can predict maintenance needs, reducing downtime and extending the lifespan of the equipment. Furthermore, AI-driven quality control systems ensure unparalleled accuracy in dimensions and aesthetics of the final product, meeting the highest standards of quality.

2. Eco-friendly Production Processes

Sustainability has become a central focus in the packaging industry, driving the adoption of eco-friendly technologies in rigid box making machinery. Modern machines are designed to minimize waste and energy consumption. They accommodate a wider range of recyclable and biodegradable materials, including paperboard and plant-based adhesives. Additionally, some advanced machines are equipped with energy recovery systems, which reuse the heat generated during the production process, further reducing the carbon footprint.

3. Customization and Flexibility

Today’s market demands unique and personalized packaging solutions. Rigid box making machinery now features advanced software that allows for easy customization of box sizes, shapes, and designs. This capability is vital for small batch productions and bespoke orders, enabling manufacturers to cater to specific customer needs without significant setup time or material waste. Digital printing technology integrated into these machines further enhances customization, offering high-quality, cost-effective printing directly on the boxes.

4. Automation and Robotics

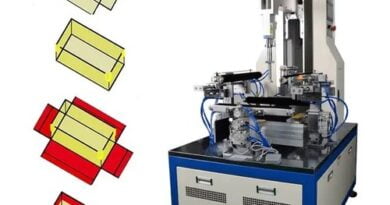

The incorporation of automation and robotics into rigid box making machinery significantly enhances production efficiency. Automated feeding systems, robotic arms for precise placement and assembly, and automatic quality checks streamline the entire production process. These innovations not only increase output but also improve worker safety by performing hazardous tasks and reducing human error.

5. Connectivity and Smart Manufacturing

The concept of Industry 4.0 has made its way into rigid box making, with machines now boasting advanced connectivity features. This connectivity enables seamless integration into wider manufacturing systems, allowing for real-time monitoring, data analysis, and remote control. Manufacturers can track production metrics, predict potential issues, and make adjustments on the fly, ensuring continuous optimization of the production process.